AUTOMATIC TOOL CHANGERS

ATI Robotic Tool Changers maintain their ultra-high repeatability over millions of production cycles as they allow manufacturers to automatically change robot end-effectors. Improving the flexibility and thereby value of a manufacturing robot is why factories around the world employ ATI Robotic Tool Changers.

Robot end-effectors have a purpose-built tool on one side, and on the other, called the master-side, they have the utility connections for electric control signals, pneumatic pressure or vacuum power, or even water and/or coolants.

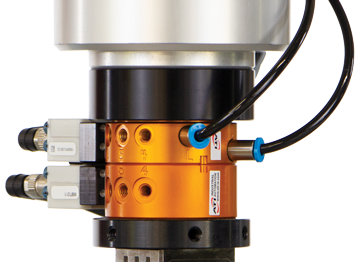

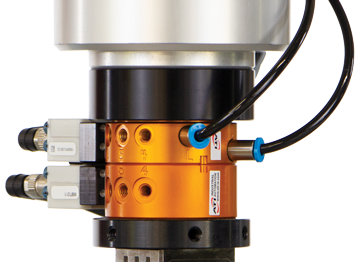

ROBOT COUPLER

The versatile ATI Robot Tool Changer allows an automated process to make necessary tool changes including passing the correct utilities from the robot arm to the end-effector. The tool side of a quick-change device connects to the gripper or other tool being used, while the master side connects directly to the robot arm.

A QC, or Quick-Change device, auto tool changer (ATC), robotic arm tool changer, robot coupler, robotic coupler, or robotic connector are all names commonly used for this piece of manufacturing equipment.

HTE Automation and ATI Industrial Automation work together to supply manufacturers in Kansas, Missouri, and Illinois with the most flexible, efficient, and long-lasting automatic tool changers available.

ATI Robotic Tool Changers maintain their ultra-high repeatability over millions of production cycles as they allow manufacturers to automatically change robot end-effectors. Improving the flexibility and thereby value of a manufacturing robot is why factories around the world employ ATI Robotic Tool Changers.

ATI Robotic Tool Changers maintain their ultra-high repeatability over millions of production cycles as they allow manufacturers to automatically change robot end-effectors. Improving the flexibility and thereby value of a manufacturing robot is why factories around the world employ ATI Robotic Tool Changers.

The versatile ATI Robot Tool Changer allows an automated process to make necessary tool changes including passing the correct utilities from the robot arm to the end-effector. The tool side of a quick-change device connects to the gripper or other tool being used, while the master side connects directly to the robot arm.

The versatile ATI Robot Tool Changer allows an automated process to make necessary tool changes including passing the correct utilities from the robot arm to the end-effector. The tool side of a quick-change device connects to the gripper or other tool being used, while the master side connects directly to the robot arm.